Cinch Connectors Ltd has invested in four Lynx Stereo Zoom Microscopes to inspect their wide range of connectors, from their Goods-In department through to their Quality Department, the microscopes are utilised by Cinch because of their superior viewing heads and quality optics.

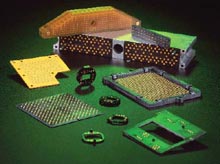

Operating since 1917, Cinch Connectors Limited, based in Nottinghamshire (and in Illinois, USA), manufacture a wide range of connectors primarily for telecommunications and transportation, in addition to supplying the aerospace and defence industry.

Cinch Connectors Limited design and manufacture a range of harnesses in addition to their range of connectors, for end user commissions to general supply of mainstream electronic distributors such as Farnell and RS Components.

High performance connectors hand assembly

Cinch’s connector and harness solutions are generally hand assembled due to their bespoke and high-end performance, and so therefore each component part and stage of assembly requires manual inspection for imperfections.

The high-end connectors (usually for defence and aerospace) are manufactured with only 10-20 units in each batch which illustrates the quality, technology and individuality of these commissioned connectors.

One such connector, the CIN::APSE is a solderless Z-axis interconnect technology that offers exceptional mechanical and electrical performance, which can be customised to users requirements.

Utilised in the aerospace industry, the CIN::APSE is an ideal solution because it is small, with low inductance, and exceptional resistance to shock, vibration and thermal cycling.

Cinch’s Microminiature Dura-Con line of connectors qualified (QPL) to MIL-DTL-83513 is one of the most widely used 0.050 inch (1.27mm) pitch connectors for military and high-end commercial applications.

Dura-Con is ideal where packaging requires a small size and low weight, as well as a highly reliable and rugged connector that has electrical and mechanical integrity under extreme vibration and shock conditions.

The heart of the Dura-Con System is the unique wire form pin that provides seven points of contact when mated to the socket.

Preventing unnecessary wastage through inspection

Whether Cinch is manufacturing a batch of CIN::APSE or a batch of their Microminiature Dura-Con connectors, 100% inspection is crucial to ensure the highest levels of quality are maintained.

For example, some of the connector bodies are supplied with nickel plating and this requires inspection in case the finish is chipped or scratched.

If the plating is imperfect on a single connector and is then built up with the harness, the harness is difficult to disassemble and therefore all of the components have to be wasted – a very expensive exercise.

Thorough manual inspection is therefore essential, making sure each component meets with the gold standard at every point of the manufacturing process, preventing unnecessary wastage.

Greater magnification without eye fatigue

In addition to the inspection of each component in the Goods-in department, Cinch utilise magnification throughout the manufacturing process, to final inspection, before the connectors are dispatched.

Most of the assembly points benefit from bench magnifiers, but with today’s technology requiring smaller, faster and robust specifications, greater magnification is required.

In addition, Cinch employ many experienced technical personnel who spend long hours inspecting components and fully assembled connectors.

This is often very tiring and so to maximise their comfort and therefore optimise accuracy and throughput, Cinch has invested in four Lynx stereo zoom microscopes from Vision Engineering Ltd.

The Lynx offers much greater magnification than the bench magnifier, with up to 120x zoom capability.

However, unlike a traditional stereo microscope, the Lynx benefits from a patented viewing head called a DynascopeTM allowing for inspection to be conducted without the disadvantage of peering through eyepieces, therefore enhancing operator comfort as well as greater accuracy and productivity.

Fig. 2.0. Shows one of the experienced technical team inspecting component parts through the Lynx’s patented viewing head.

Superior optical viewing with image capture

Offering superior optical views of component parts, the Lynx allows users to inspect in high resolution, contrast and clarity, in addition to the advantages of the long working distance and wide range of accessories such as digital image capture options for reporting.

This allows for a wide range of parts to be inspected for possible imperfections including: wicking of the pins; quality of the solder joints; or general damaged caused during the assembly process.

With some of the connectors used in critical applications such as aerospace, it is essential the connectors and harnesses are supplied to customers at the high standard they require from Cinch Connectors Limited.

With technology evolving, so both speed and size are key requirements, Cinch Connectors are continually exceeding their customer’s expectations by providing innovative solutions to the rapidly changing needs of the markets.

Their investment in technology and capable instrumentation (such as the Lynx), makes sure there are no limitations when it comes to connector capabilities or any compromises on quality or functionality.